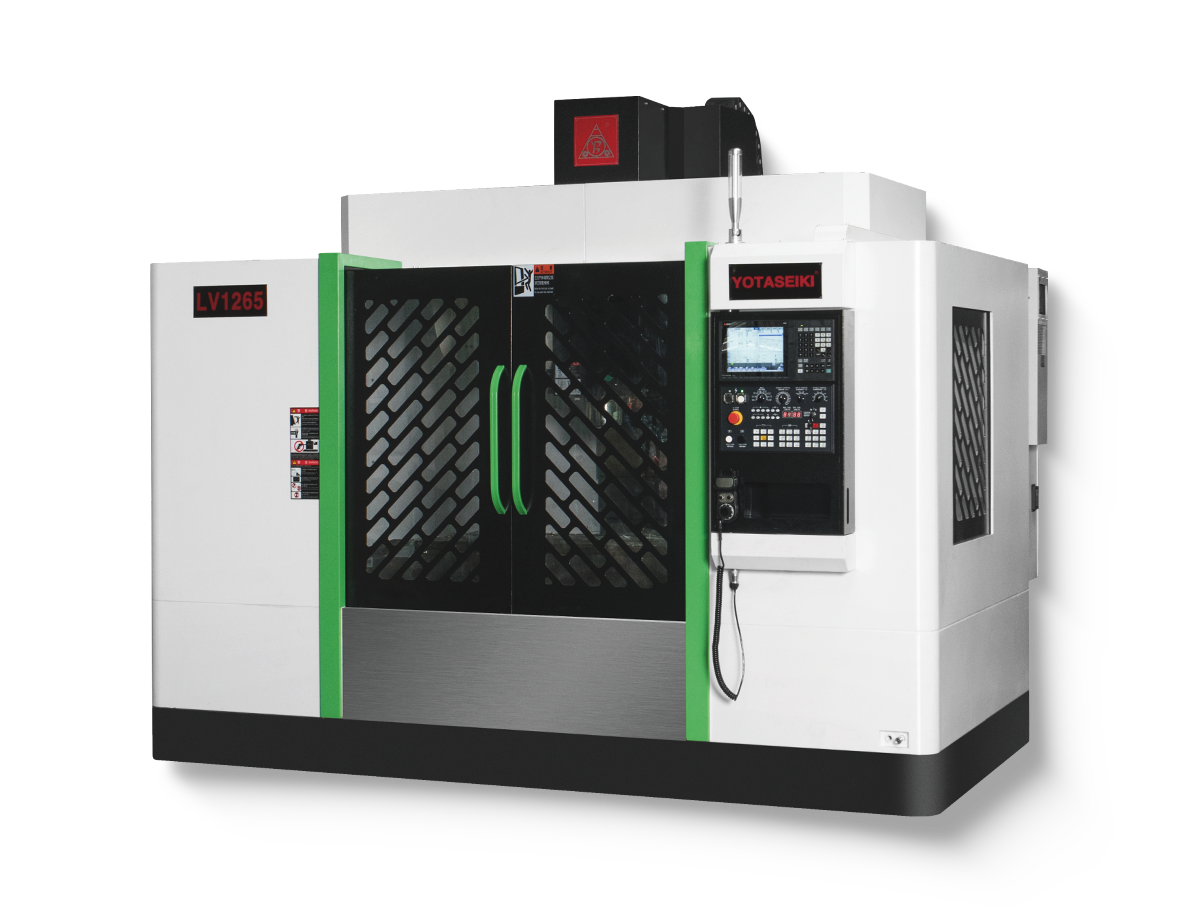

YOTASEIKI

LV960 High speed Machining Center

LV960 High speed Machining Center

The LV960 linear rail vertical machining center is a small-to-medium sized machine tool that can automatically and continuously complete multiple processes such as milling, drilling, boring, expanding, reaming, spot facing, and tapping after a single fixture of the workpiece. The machine tool is suitable for processing multiple varieties of small and medium-sized complex parts such as small and medium-sized boxes, plates, disks, valves, shells, molds, etc. The machine tool uses high-precision linear rails and screw rods, which provide better dynamic response and can achieve high-speed cutting with low-speed no-creep. It is widely used in the precision parts, 3C products, hardware, auto parts, medical equipment industries.

The whole machine structure is fixed column type, cross slide table structure. The machine body adopts a super-large stable base, high-rigidity large-span herringbone column, and high-speed cutting without vibration and deformation.

PARAMETERS

| ITEM |

Unit | Parameters: | Remarks |

| Capacity | |||

| X-axis travel | mm | 900 |

|

| Y-axis travel | mm | 600 | |

| Z-axis travel | mm | 700 | |

| Distance from table(pallet) top to spindle end | mm | 110-810 | |

| Table | |||

| Table size | mmxmm | 1060×580 | |

| Permissible mass of workpiece | kg | 800 | |

| Table working surface configuratin | mm | 5-18Tx100 | |

| Spindle | |||

| Spindle motor | Kw | 7.5 | |

| Spindle speeds | rpm/min-1 | 100-12000 | |

| Spindle size | mm | φ150 | |

| Spindle nose | BT40 | ||

| Guide way | |||

| X guide | mm | 2-35 Ball screw | |

| Y guide | mm | 2-45 Ball screw | |

| Z guide | mm | 2-45 Ball screw | |

| Power sources | |||

| Screw X/Y/Z | mm | 4010/4010/4010 | |

| Motor power X/Y/Z | kw | 2.0/2.0/3.0 | |

| Feedrate | |||

| Rapid traverse | mm/min | 1-10000 | |

| X、Y、Z Rapid traverse | m/min | 36/36/36 | |

| Accuracy | |||

| Positioning accuracy(X/Y/Z) | mm | 0.01 | GB/T18400.4 |

| Repeatability(X/Y/Z) | mm | 0.007 | GB/T18400.4 |

| A.T.C | |||

| Tool capacity | 24 | ||

| Max. tool mass | kg | 7 | |

| Max. tool length | mm | 250 | |

| Miscellaneous | |||

| Control system |

/ | Mitsubishi M80 | |

| Compressed air flow rate | L/min | ≥280(ANR) | |

| Compressed air pressure | MPa | 0.5-0.8 | |

| Electrical power supply | KVA | 25 | |

| Floor space | mm | 2700*2500*2850 | |

| Mass of machine | Kg | 6200 | |

LV960 Vertical Machining Center

❉The whole machine is fully enclosed and protected, with a beautiful shape and easy operation and maintenance.

❉The large parts of the foundation are made of high-quality resin sand molding and high-strength cast iron materials, which gives the machine high rigidity and stable accuracy.

❉The three-axis guideway is loaded by roller linear guide, which features high rigidity, low friction, and low noise.

❉Large diameter C3 grade screw rod with pre-tensioning structure to eliminate some thermal extension, self-lubricating screw rod bearing to extend bearing life.

❉The knife library uses 24 knife arm type knife libraries with reliable quality and stable performance.

❉The spindle adopts a high-speed spindle unit with direct BT40-12000rpm/min. The front end of the spindle adopts a labyrinth design with air curtain protection to prevent cutting fluid from entering the spindle bearing.

❉ Equipped with positive displacement and forced lubrication systems to ensure good lubrication of all moving parts of the machine.

❉The dual-layer water tank filtration system structure provides good cutting fluid for workpiece processing.

❉Equipped with a high-performance Mitsubishi M80 CNC system, it ensures the stability of machine control and also guarantees the CNC machining functions and auxiliary functions required by users.

CONTACT US